Click here for examples of geothermal power generation

Click here for examples of factory waste heat power generation

Click here for examples of biomass power generation

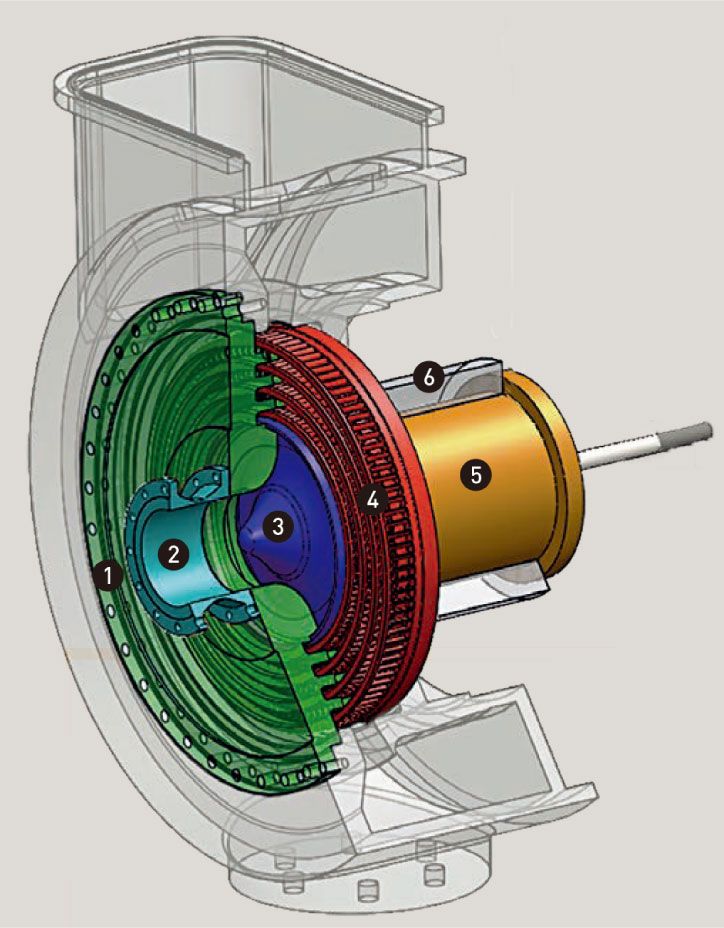

What is the working medium of EXERGY?

Normally, at most 2~3 types of heat carriers are used in binary power generation, but EXERGY can use 11 types of heat carriers depending on the application of the heat source.

Since it can handle a temperature range from 90 ° C to 350 ° C, in addition to the above examples, waste heat from industrial processes such as concentrating solar power generation (CSP: Concentrating Solar Power), steel mills, glass factories, cement plants, industrial waste treatment plants, various furnaces, waste heat from diesel generators and gas turbine generators, recovered heat from gas compression plants, It can be used for a variety of applications, including solar thermal power generation.